Safety bollard buyer’s guide

In industrial environments, safety is all about preventing accidents and minimizing damage. High-quality safety bollards represent a crucial investment for achieving this. Bollards keep your valuable machinery and critical infrastructure protected from the unavoidable: impacts. But how do you choose the right safety bollard for your specific situation? What should you look for during the purchase process, how do you keep under budget, and what about certifications and standards?

This buyer’s guide summarizes all the essential elements to help you make an informed decision.

Table of contents

What should you consider when purchasing safety bollards?

What are safety bollards intended to protect?

Learn why investing in safety bollards is crucial for protecting your machinery, infrastructure, and buildings.

Selection criteria: What should you look for when choosing safety bollards?

Which factors determine which safety bollard is right for you? Considering these factors ensures that the safety bollards you purchase meet your environmental, operational, and safety requirements.

How busy is the work area, and what types of vehicles are being operated?

Understand how traffic density and vehicle type affect your purchase of safety bollards.

What are the key features of safety bollards?

Learn about essential features like impact resistance, sustainability, and visibility—factors that determine the effectiveness of a safety bollard.

When it comes to safety bollards, you should consider ease of installation, possible placement, and expandability. Learn how you can reduce installation costs and prevent unnecessary downtime.

What should you do after a collision?

Learn what to do after a collision in order to minimize further damage and safety hazards.

What is your budget, and what are the long-term costs?

How do you create a budget, and why is it important to look beyond the initial purchase price?

Certification and standards: What should you look for?

Learn how the right certifications ensure product quality and reliability.

Conclusion: Safety as a smart investment

Tailored advice

What should you consider when purchasing safety bollards?

Are you considering an investment in safety bollards? There are several factors you should take into account, including the risks in your work environment, the density of vehicle traffic, and the level of protection required. At Boplan, we’re happy to help you make the right decision.

Would you like a quote or more information about our safety bollards? Contact our expert team for tailored advice and practical tips.

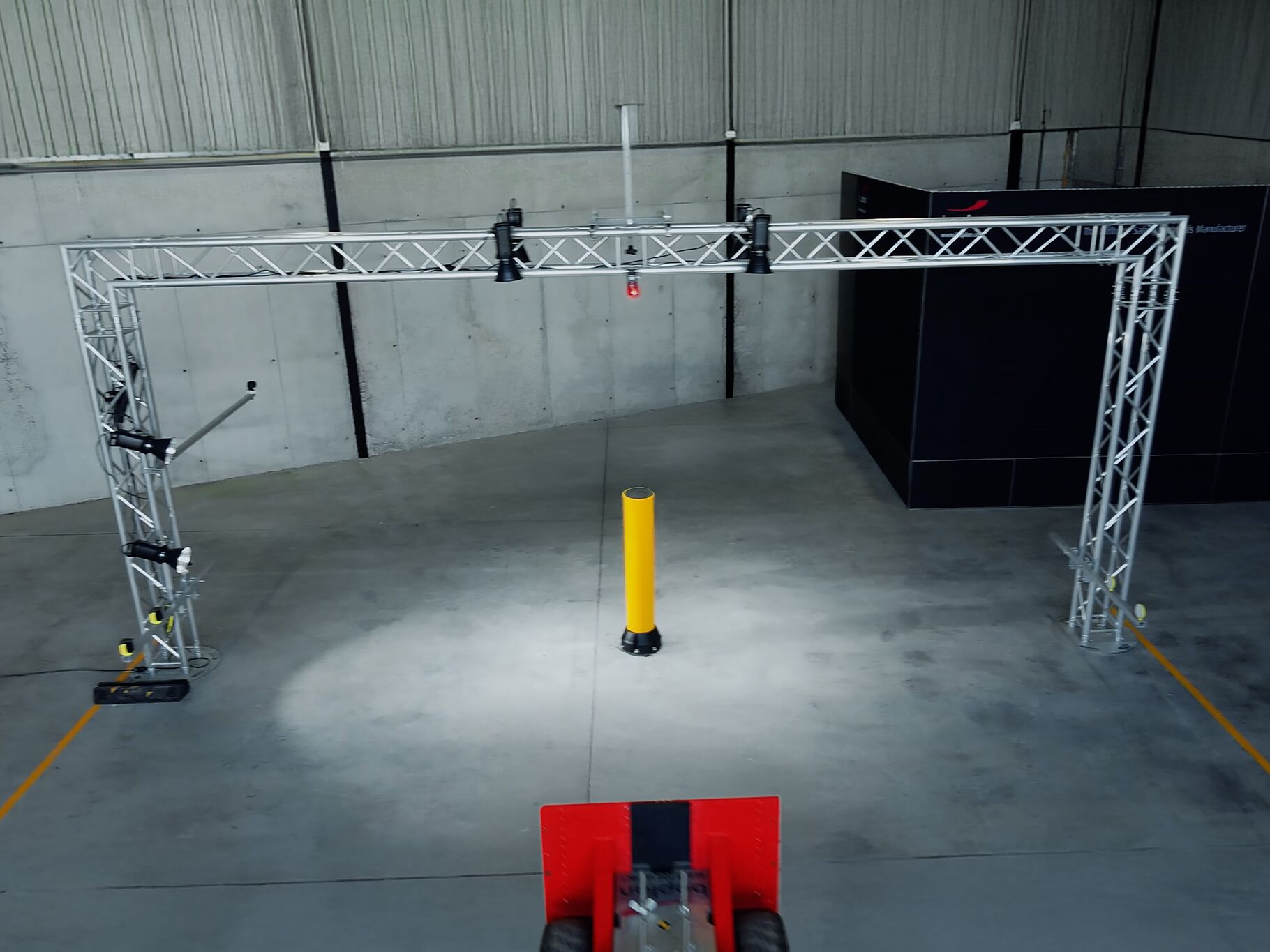

What are safety bollards intended to protect?

Safety bollards protect many critical areas in industrial environments.

Equipment and machinery

Machinery and installations are valuable and essential parts of your production process. Any collision or damage can result in extended downtime and costly repairs. Safety bollards absorb impacts and prevent direct contact with machines, loading stations, and sensitive equipment. This not only reduces repair costs, it also helps prevent production downtimes and operational losses.Buildings and infrastructure

Buildings, loading bays, gates, and walls are constantly exposed to collisions. Without proper protection, this infrastructure is at risk of serious damage in every collision. Bollards provide a strong, sustainable buffer that protects the building itself, reducing maintenance costs and extending the lifespan of your infrastructure.

Selection criteria: What should you consider when choosing a safety bollard?

There are many different types of bollards available. To ensure that you select the right bollard, it is important to consider several key factors from the beginning. Below are the most important selection criteria for helping you determine which bollard is best for your specific needs and work environment.

4. Ease of installation

Safety bollards should be easy to install—without complex procedures or lengthy downtimes. That’s why you should look for:

- A modular, easy-to-install solution.

- A bollard that can be replaced quickly and with minimal work after an impact.

5. Compliance & Certification

Quality and safety must be guaranteed. Always check whether safety bollards comply with recognized safety standards and certifications like:

- TÜV NORD certification, which confirms that the bollard meets strict safety and quality standards.

- Testing standards such as PAS 13 and UNI/TS 11886-1, which guarantee the declared level of performance.

- Sustainability guidelines, e.g., 100% recyclable, as well as environmental regulations.

By weighing these criteria carefully, you can make an informed choice and invest in safety bollards that match your safety requirements and your budget. Expert advice will also make your decision even easier.

How busy is the work area, and what types of vehicles are being operated?

There are 4 factors to consider when determining how to deal with moving traffic in your workplace.

- What type of traffic is there on site?

In environments with heavy-duty vehicles, e.g, forklifts and trucks, robust safety bollards are needed to absorb the high impact forces. In areas with lighter vehicles, e.g., hand carts and pallet trucks, less robust bollards are often sufficient.

- How busy is it, are there peak times?

In constantly busy work areas or during peak times, it is essential to install robust safety bollards. In environments with frequently moving vehicles or high traffic flows, bollards must be capable of withstanding repeated impact and prolonged stress.

- How fast do the vehicles move?

The vehicle speed determines which safety bollard to choose. The faster the vehicle moves, the greater the force of impact during a collision. In areas where higher speeds are permitted, shock-absorbing bollards must be used to absorb and dissipate the larger forces.

- How heavily loaded are the vehicles?

The vehicle load determines the amount of force exerted on the safety bollard during a collision. Heavily loaded vehicles have longer braking distances and cause more damage on impact. This means that reinforced protection is required for critical areas.

What are the key features of safety bollards?

When deciding to invest in safety bollards, it is essential to consider their key features. This helps you determine how effectively they will protect your workplace, how sustainable they are, and how much you can save on costs. Below is an overview of the most important functions and features to help you make the right decision.

1.What is the bollard's impact resistance?

How much of the impact force should the safety bollard absorb to limit the damage to vehicles, infrastructure, and goods? Choose safety bollards made from flexible polymer. This material temporarily deforms on impact and then returns to its original shape afterward.

2. Material and sustainability

Polymer bollards are resistant to corrosion, unlike their steel counterparts. This significantly reduces maintenance and replacement costs. In industrial or chemical environments, it is also important that the chosen bollards be resistant to UV radiation, extreme temperatures, and chemical exposure.

Thinking about polymer safety bollards? Make sure they are 100% recyclable. This way, you can make a sustainable investment while reducing your environmental footprint.

3. Safety and ease of use

- Finger safety: Look for additional safety features like Boplan’s Base Defender, which helps prevent fingers from becoming trapped between the bollard and a hand cart, for example.

- Some safety bollards also protect mounting bolts from damage.

- Choose bollards in high-visibility colors or with reflective strips to reduce the risk of collisions.

Four key considerations when installing safety bollards

Correct installation is key for ensuring the effectiveness and sustainability of safety bollards. Here are a few key factors to consider:

2. Who handles the installation?

Some bollard systems can be easily installed in house, while more complex setups require professional installation. It is important to check in advance whether certified technicians are needed, and how this will affect your project timeline.

4. Flexibility and future expansion

Industrial environments are often subject to change. It is important to choose safety bollards that are easy to reposition as your infrastructure evolves.

Tip: Plan the installation to minimize the work disruption in the area, and use professionals to ensure optimal performance.

What should I do after a vehicle collides with a bollard? 3 steps

A safety bollard proves its worth whenever a collision occurs. But what exactly should you do after a collision? To quickly restore safety for your staff and infrastructure, follow the steps below:

1. Collision checklist

After each collision, carefully go through the following checklist:

Safety bollard itself

Check whether the bollard has fully returned to its original shape after impact. Although polymer safety bollards absorb impacts well, it is important to check for any permanent deformation or visible cracks.

Base plate and fixings

Also inspect the base plate and fixings that anchor the bollard to the floor. Make sure everything is still secure and undamaged.

Surrounding environment

Check for any indirect damage to surrounding infrastructure, machinery, or goods.

2. Damage? Repair it as soon as possible

The sooner you make an environment safe again, the lower the risk of further damage or injury. A damaged bollard may be unable to provide protection and could fail to stop a forklift during a subsequent collision. This poses a serious safety risk. Mark off and isolate the damaged area with safety tape or temporary barriers until repairs are completed.

3. Choose modular systems

With a modular system, you only need to replace damaged parts rather than the entire structure. This not only lowers costs, it also reduces production downtimes. For maximum flexibility, choose a system that is easy to expand and adapt.

By responding quickly and properly after a collision, you maximize the benefits of polymer bollards and minimize further costs and risks.

What is your budget, and what are the long-term costs of safety bollards?

When investing in safety bollards, your available budget naturally plays a key role. However, it is crucial that you look beyond the initial purchase price and consider what the bollard delivers in the long term—especially how much money it can save you. Below, we explain how to best assess these costs:

Budget: Look beyond the purchase price

The unit price matters, of course, but don’t base your decision solely on this direct cost. Pay close attention to the type of polymer safety bollard you need: bollards for high-impact areas typically require a larger investment, while lighter models may be sufficient in low-traffic zones. Carefully calculate how many bollards you need and where they will be installed. This helps avoid unexpected costs later. Don’t forget to account for optional extras, e.g., reflective strips, to maximize visibility.

Read our blog to learn more about the benefits of polymer safety solutions over steel or concrete alternatives.

Certifications and standards for safety bollards: What should you look for?

When purchasing safety bollards, always check that they comply with applicable standards and certifications. Certification serves as proof that the bollards are safe, reliable, and effective. What should you focus on?

TÜV Nord certification: Independently tested

TÜV NORD certification is one of the most important certifications for safety bollards. This independent assessment confirms that the bollards have been rigorously tested for impact resistance, safety, and quality. TÜV NORD-certified safety bollards deliver proven protection in line with recognized international standards.

Testing standards: UNI/TS 11886-1

Check whether the safety bollards have been tested in accordance with recognized impact standards such as UNI/TS 11886-1. This standard ensures that the bollards have been effectively tested under realistic impact conditions, guaranteeing reliable protection for your specific work environment.

In many cases, a tailored approach is the best option. Do your safety solutions need to meet specific standards? At Boplan, we are happy to advise you and provide you with a tailored solution that fits your industry and work environment. Get in touch with us before making your final decision.

Conclusion: Safety as a smart investment

By investing in high-quality polymer safety bollards, you benefit from immediate protection and visible safety as well as significant long-term savings. Less maintenance, less damage, less downtime, and fewer hazards make safety bollards a smart and sustainable investment.

Safety bollards are rarely the only solution

Combine with other safety solutions

Safety bollards protect critical areas from collisions, but they are rarely a standalone solution. In practice, they are often used alongside guardrails, pedestrian safety systems, or flexible machine protection equipment. Because our safety solutions are modular, they connect seamlessly with one another. This enables you to build a complete and efficient safety system tailored to the hazardous areas of your workplace.

Also explore our industrial safety barriers buyer’s guide and learn how this safety solution is perfect for use in combination with safety bollards.

Frequently asked questions (FAQ) about safety bollards

1. Which bollard do I need?

Use our Boplan Impact Calculator to quickly and easily determine which safety bollard is best for your requirements.

2. How do I calculate the impact level that my bollards will have to withstand?

Determine the required impact level based on factors like vehicle weight and speed as well as the type of traffic in your work environment. Our Impact Calculator will guide you step by step.

3. What is the difference between polymer safety bollards and metal or concrete bollards?

Polymer bollards absorb the impact more effectively and return to their original shape. Metal or concrete bollards are rigid and typically need to be replaced following an impact. Want to know more? Read our blog: Polymer vs steel.

4. Can I install safety bollards myself or do I need professional help?

Modular bollards are normally easy to install. Professional installation is recommended for more complex bollards or specific environments. Refer to the respective product’s installation guide for details.

5. What maintenance do safety bollards require, and what are the maintenance costs?

Polymer bollards require very little maintenance. A periodic visual inspection is usually sufficient.

6. How sustainable are polymer safety bollards, and are they recyclable?

Our polymer safety bollards are 100% recyclable, have a long service life, and contribute to sustainable site management. Learn more on our sustainability page.

7. Can safety bollards be used outdoors, and are they weather-resistant?

Yes, our polymer bollards are designed for outdoor use and are resistant to UV radiation, moisture, and extreme temperatures. Explore our outdoor safety solutions.

8. What happens to safety bollards after a collision? Do I always need to replace them?

Thanks to their flexibility, polymer safety bollards naturally return to their original shape after an impact. In case of severe damage, you only need to replace the affected equipment.

9. How quickly can I order safety bollards and when will they be delivered?

The delivery time depends on the type and quantity of bollards ordered. Standard models are typically available on short notice. Contact us for a personalized quote and delivery estimate.

10. What warranty should I get when purchasing safety bollards?

Boplan offers standard warranties that vary by product type. For full details on our warranties, please contact our team directly.