Buyer’s guide: safety barriers and handrails

In industrial settings like warehouses, production plants, and logistics centers, vehicles such as forklifts and pallet trucks are crucial to daily operations. However, these vehicles also bring serious risks to people and infrastructure. That's why smart safety planning—with well-placed safety barriers and strategically positioned handrails—is essential to preventing accidents and maintaining a secure workplace. Flexible safety barriers absorb impacts, while sturdy handrails help define safe zones and direct traffic flow.

In this buyer’s guide, we’ll walk you through the key factors to consider when choosing safety solutions.

Table of contents

What should you look for when buying safety barriers and handrails?

What should the safety barrier protect?

Is the barrier protection intended to protect employees, warehouse racks, machinery, loading bays, or critical infrastructure? Your answer will help determine the best type of barrier for your application.

What should handrails protect?

Do you need to protect pedestrians from vehicle traffic? Are the handrails meant for machine guarding or separating different work zones? The handrail's purpose will guide you in selecting the right height and impact strength.

What are the environmental factors?

Is the safety equipment intended for indoor use or outdoor use? Will it face exposure to extreme temperatures, humidity, or chemicals?

How busy is the work area, and what types of vehicles operate there?

In busy environments like warehouses with constant forklift traffic, you’ll need tougher, more impact-resistant safety barriers than in quieter zones. Vehicle speed and weight also matter when picking the right safety barrier.

What are the key features of safety barriers and handrails?

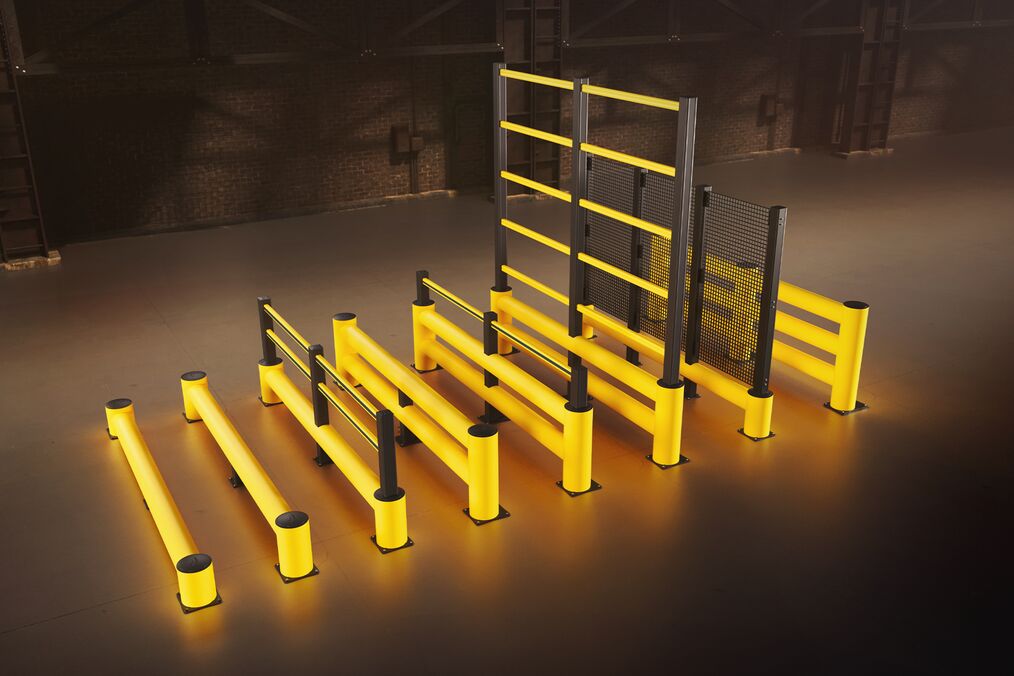

Focus on flexibility, impact resistance, sustainability, and visibility. Flexible polymer barriers absorb impacts and return to shape. This make them longer-lasting than metal alternatives.

What about installation?

Need a quick setup with minimal interruption? Modular systems install easily and expand as needed, keeping downtime to a minimum.

What about maintenance?

High-quality safety solutions need less maintenance. Flexible barriers outperform steel ones, which can bend or break on impact.

What happens in a collision?

How much impact can the barrier or handrail handle? What happens to the barrier or handrail after a collision? Good solutions prevent damage to both vehicles and infrastructure.

What is the budget and the long-term cost?

Cheaper options may seem attractive at first, but frequent repairs and replacements drive up costs. Invest in a long-lasting safety solution that delivers a lower total cost of ownership.

Which certifications and standards matter?

Does the safety barrier or handrail meet the relevant US standards and hold certifications such as TÜV Nord or ISO? These certifications guarantee quality, durability, and reliability.

Tailored advice

Looking to invest in safety barriers and handrails? Make sure to consider several factors, such as the specific risks in your workplace, the amount of vehicle traffic, and the level of protection you need. At Boplan, we're ready to help you find the right solution.

Want a quote or more information about our safety barriers or handrails? Reach out to our team for expert advice and hands-on guidance.

What should the safety barrier protect?

Safety barriers protect several critical zones within an industrial environment. Depending on what needs to be secured, you can choose specialized types of barriers:

1. Employees and other people

In areas where pedestrians move—such as walkways and crossings—high-visibility, impact-resistant flexible barriers are essential. They keep people safely separated from vehicles and help minimize the risk of serious injury in the event of a collision.

2. Equipment and machinery

Industrial machinery is valuable and often sensitive. Vehicle collisions can lead to expensive repairs, production downtime, and potential safety hazards. Strong, flexible barriers protect equipment while maintaining easy access.

3. Buildings and infrastructure

Structural elements like columns, loading docks, electrical units, and walls are particularly vulnerable to vehicle impacts. Properly positioned barriers or handrails help prevent these structures from damage and avoid costly repairs.

4. Goods and storage racks

Storage racks with goods are highly susceptible to forklift impacts. Safety barriers help reduce the risk of rack collapse and prevent stored goods from falling or being damaged.

When selecting safety barriers, always consider both the level of risk and the required degree of protection. In high-traffic areas, durable, impact-absorbing barriers are the best choice. In lower-risk zones, lighter protection may be enough.

What should handrails protect?

Handrails are crucial for protecting people in industrial environments. Depending on the application, specific handrail features might be required:

What are the environmental factors where the safety barriers and handrails are installed?

5 key environmental factors to keep in mind:

1. For indoor and outdoor use

Outdoor safety barriers and handrails must withstand exposure to rain, frost, and UV radiation. For outdoor use, choose materials with high corrosion resistance.

2. Temperature fluctuations

In extreme environments—such as cold storage facilities or areas near heat sources—materials must handle expansion, shrinkage, and brittleness.

3. Chemical exposure

In sectors like the chemical industry, safety solutions must withstand aggressive substances and corrosive chemicals. Polymer barriers outperform metal alternatives because they don’t rust and offer better chemical resistance.

4. Space available

In narrow aisles or tight production spaces, safety barriers should be compact and efficient. Modular or low-profile barriers are ideal for tight areas, allowing safe movement for both vehicles and pedestrians.

5. Sector-specific requirements

Different industries have different safety needs. Let's take the food industry as an example. Strict hygiene rules apply here. Barriers and handrails must be easy to clean and designed to prevent contamination. Smooth surfaces and rounded corners help prevent dirt buildup and support better hygiene.

How busy is the work area, and what types of vehicles operate there?

5 key traffic and vehicle factors to evaluate:

1. What type of traffic is there on site?

In environments with heavy-duty traffic, such as forklifts and trucks, you’ll need robust safety barriers that can absorb high-impact forces. In areas used mainly by lighter vehicles like hand carts or pallet trucks, lighter protection may be enough.

2. Is there mixed traffic?

In many workplaces, pedestrians and vehicles share the same space. In these environments, a combination of clear floor markings, handrails, and traffic guidance systems is crucial to prevent collisions. Pay special attention to crossings and areas where people and vehicles may intersect.

3. How busy is it and are there peak times?

In busy areas or during peak times, it’s crucial to install stronger safety systems to ensure continuous protection. Where vehicle maneuvering is frequent and traffic is heavy, barrier systems must handle repeated impacts and continuous loads.

4. How fast do the vehicles move?

Vehicle speed directly impacts the choice of safety barriers. The faster the vehicles move, the greater the force during a collision. In areas where higher speeds are allowed, shock-absorbing safety barriers must be installed to effectively absorb and distribute impact energy.

5. How heavily loaden are the vehicles?

Vehicle load affects the collision force. Heavily loaded vehicles have longer braking distances and cause more severe damage on impact. This requires stronger protection, like reinforced safety barriers and handrails, especially in high-risk zones.

What are the 4 key features of safety barriers and handrails?

If you are investing in safety barriers and handrails, focus on these essential features:

2. Sustainability

How long do your safety barriers and handrails need to last? In high-traffic industrial environments, durability plays a major role in lowering overall costs. Flexible polymer safety barriers typically outlast metal alternatives, which can bend or break on impact and often need replacement. Flexible barriers absorb energy and return to their original shape, minimizing damage to vehicles and infrastructure.

4. Are they clearly visible?

Safety products must be easily noticeable for both drivers and pedestrians. Key visibility factors to consider:

- Color: Bright, high-contrast colors like yellow and black make barriers stand out clearly.

- Height and diameter: Taller barriers and wider bollards improve visibility and increase situational awareness.

- Size and placement: Smartly placed safety elements help prevent accidents by signaling danger early enough.

What about installation?

Correct installation is critical to the long-term effectiveness and durability of your safety barriers and handrails. Here are 4 key factors to think about when setting up safety barriers and handrails:

1. Is quick installation important?

In workplaces where downtime is costly, fast and simple installation becomes a top priority. Modular safety systems are the best choice because they can be set up quickly with minimal disruption.

2. Who will handle the installation?

Some safety solutions are DIY-friendly, while others require trained professionals. It’s important to check ahead whether certified installers are necessary—and whether that affects your project timeline.

3. Are there any site restrictions?

In some environments, drilling or anchoring into the floor isn't allowed—for example, in clean rooms, cold storage facilities, or warehouses with underfloor heating. In these cases, consider alternatives like chemical anchors or freestanding systems.

4. Flexibility and future expansion

Industrial environments constantly evolve. Choose safety solutions that are easy to adapt or extend as your infrastructure grows.

Tip: Plan your installation to minimize disruption to daily operations. Get professional help to ensure your system works exactly as intended.

What about maintenance?

Maintenance is a key factor when choosing safety solutions. It impacts not just the product’s lifespan, but also your total cost of ownership over time. Here are a few important aspects to keep in mind when evaluating safety barriers and handrails:

Are parts replaceable, or must the entire system be replaced?

Some safety systems allow individual components to be replaced, while others require a full system replacement after an impact. Flexible polymer protection typically returns to its original shape after a collision, meaning replacement is often unnecessary. With steel or concrete, however, deformation is permanent. In most cases, the entire barrier must be replaced.

What happens in the event of a collision?

Polymer safety barriers and handrails

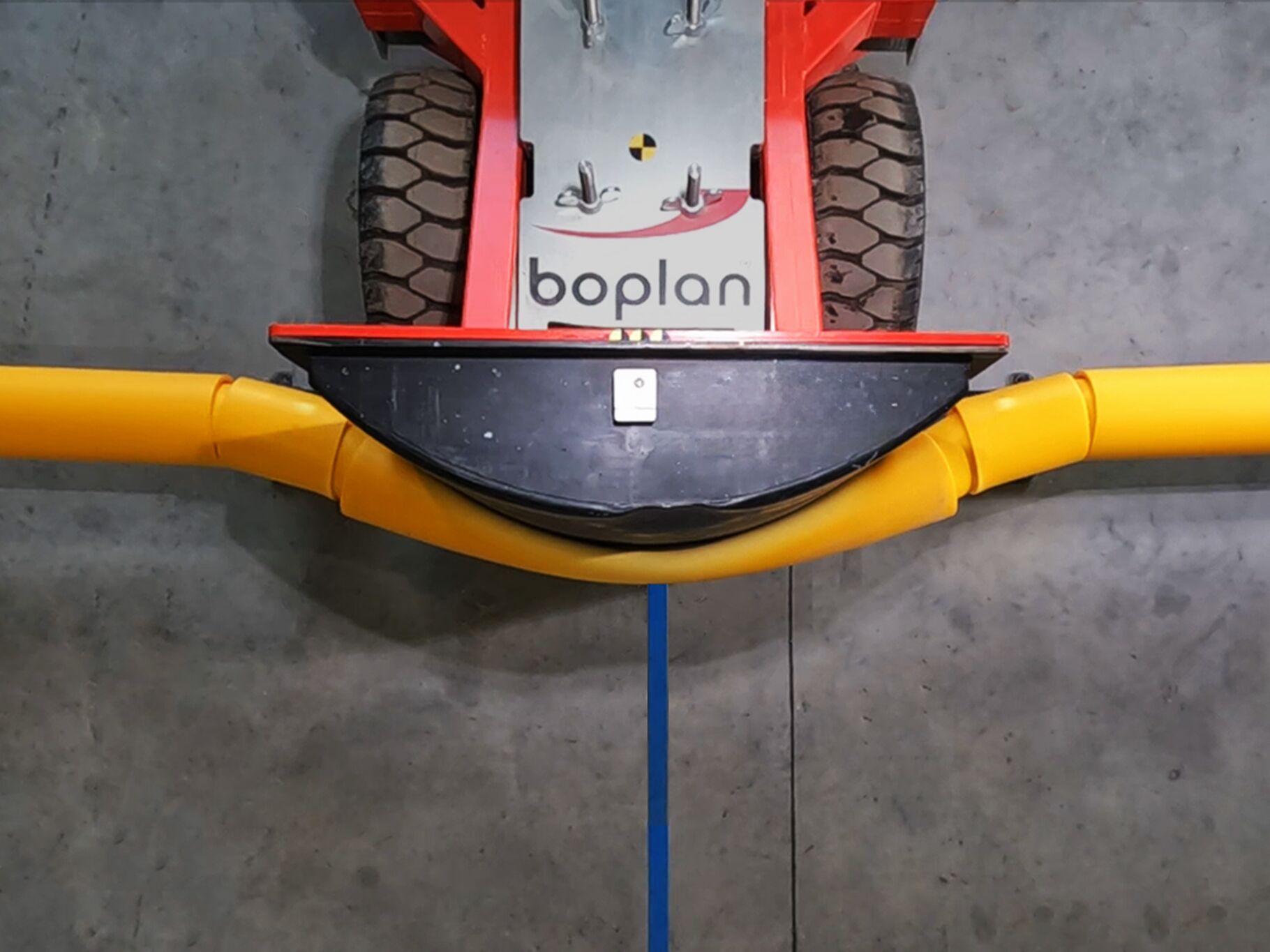

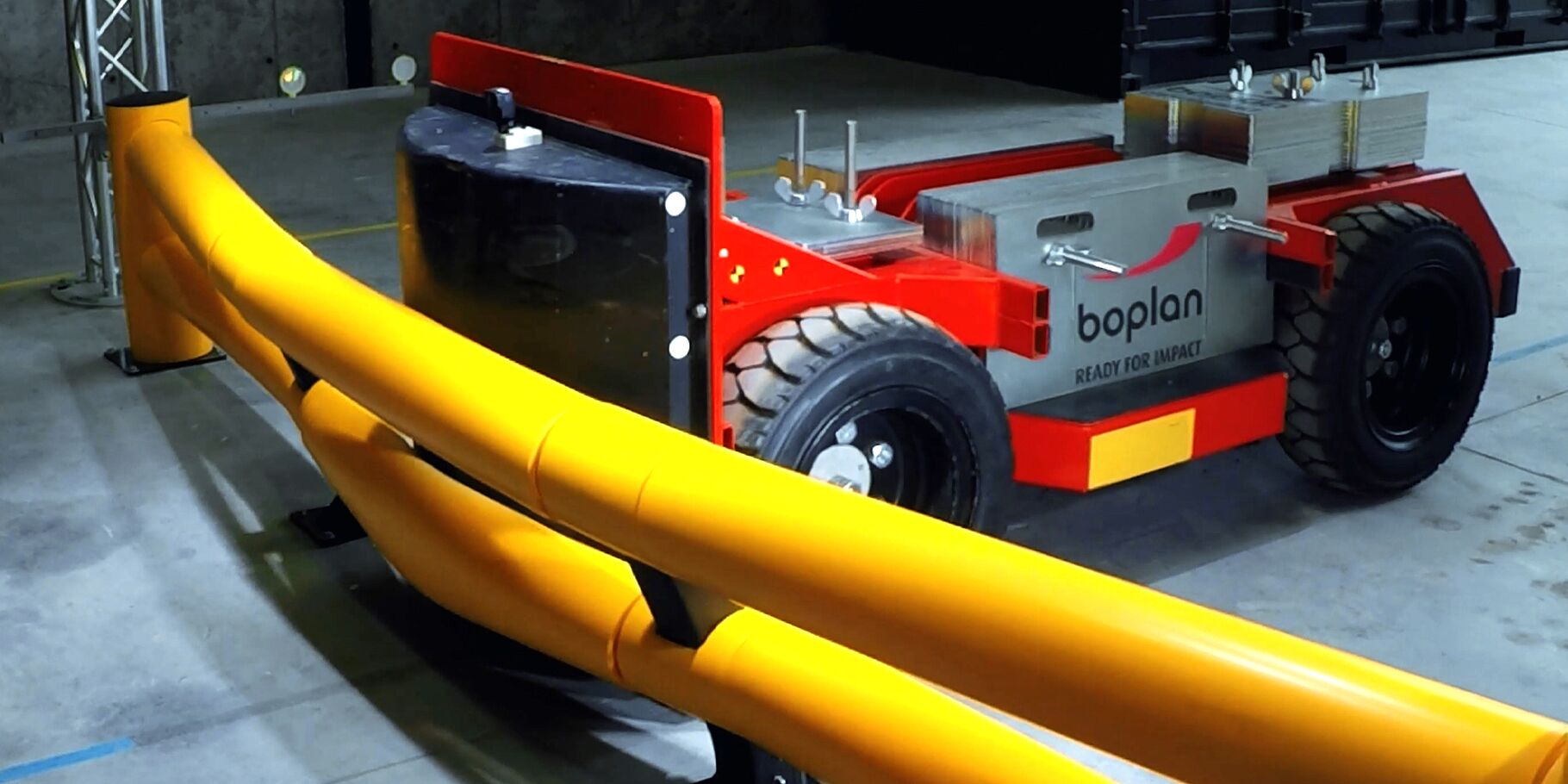

Picture the worst-case scenario: a forklift strikes a safety barrier or handrail. What happens next?

Polymer safety barriers and handrails are built to absorb multiple impacts without suffering permanent damage. Their flexible design allows them to absorb the force and return to their original shape. As long as you stay within the recommended parameters, polymer safety systems deliver a lifespan that goes beyond expectations.

Damage? Repair it right away

Has damage occurred? If so, make repairs as quickly as possible. A compromised safety system can no longer perform properly and may fail during a future impact with a vehicle. This creates a serious safety risk. Mark and isolate the damaged area with safety tape or temporary barriers until repairs are completed.

Save costs with modular systems

One major advantage of modern safety barriers and handrails is their modular design. Instead of replacing the entire system, you can simply swap out the damaged part. This approach lowers costs and minimizes manufacturing downtime. For maximum flexibility, choose systems that are easy to expand and adapt as your facility grows.

By investing in flexible, modular, and sustainable safety solutions, you minimize the impact of collisions and keep your workplace fully protected at all times.

What is the budget and what are the long-term costs?

When buying safety barriers and handrails, two major financial factors come into play: your upfront investment and your long-term costs.

Costs of damage: prevention or repair?

A critical financial question is whether you want to spend on frequent repairs—or invest upfront in a resilient system that prevents damage in the first place. Flexible polymer barriers absorb impacts and spring back into shape, reducing damage to both the barrier and the vehicle. Modular systems allow you to replace only the damaged parts, not the entire system. This cuts repair costs and speeds up recovery with minimal disruption.

Which certifications and standards matter?

What safety standards must safety barriers and handrails meet?

Certifications and standards are crucial when choosing safety barriers and handrails. They guarantee that the products meet strict safety and quality requirements—essential for industrial environments.

Depending on your sector and application, safety products must comply with specific standards. Always check that the products are tested for impact resistance and shock absorption by an accredited testing center. You’ll usually find this information in technical documents like data sheets.

Trustworthy safety products comply with recognized standards, including:

- ISO (International Organization for Standardization) – sets international requirements for quality and safety.

- US standards – determine whether a product complies with US industrial regulations.

- EN standards (European Standards) – determine whether a product complies with European industrial regulations.

- TÜV certification – offers additional assurance from an independent testing organization.

Some companies also set internal safety guidelines or protocols that go beyond legal requirements. Be sure the safety barriers and handrails you select align with your company's internal policies and procedures.

In many cases, a custom-tailored proposal is the smartest option. Do your safety solutions need to meet specific standards? At Boplan, we’re happy to advise and create a tailored solution that fits your sector and work environment. Reach out to us before making your final decision.

Conclusion

When choosing safety barriers and handrails, several critical factors must be considered: workplace risks, traffic type and intensity, environmental conditions, and certification requirements.

Need expert advice on the best safety barriers or handrails for your business? Contact our team today. We’ll be happy to help you find a sustainable, flexible solution for protecting your people, equipment, scaffolding, infrastructure, and buildings.