Why polymer safety solutions are preferred in industrial environments

Safety is a top priority in industrial environments. Choosing the right collision protection is critical. While traditional steel safety solutions have long been the standard, the introduction of high quality polymer safety products has revolutionized the industry. Here are some compelling reasons why polymer protection is almost always the best choice compared to steel solutions.

Excellent shock absorption and equal or greater strength

Polymer safety solutions are distinguished by their impressive shock-absorbing properties. This means that in the event of a collision, the impact is absorbed and distributed over a larger surface area, which minimizes damage to both the safety equipment and the vehicle. Polymer crash protection has similar properties as steel in terms of strength but is non-destructive. As a result, polymer offers superior protection compared to steel, which directly absorbs the force of a collision.

Lightweight and easy to install

Polymer safety products are significantly lighter than steel, which makes them easier to install and reduces the overall load on the infrastructure. This makes them a cost-effective choice, especially on large projects where multiple safety elements need to be installed.

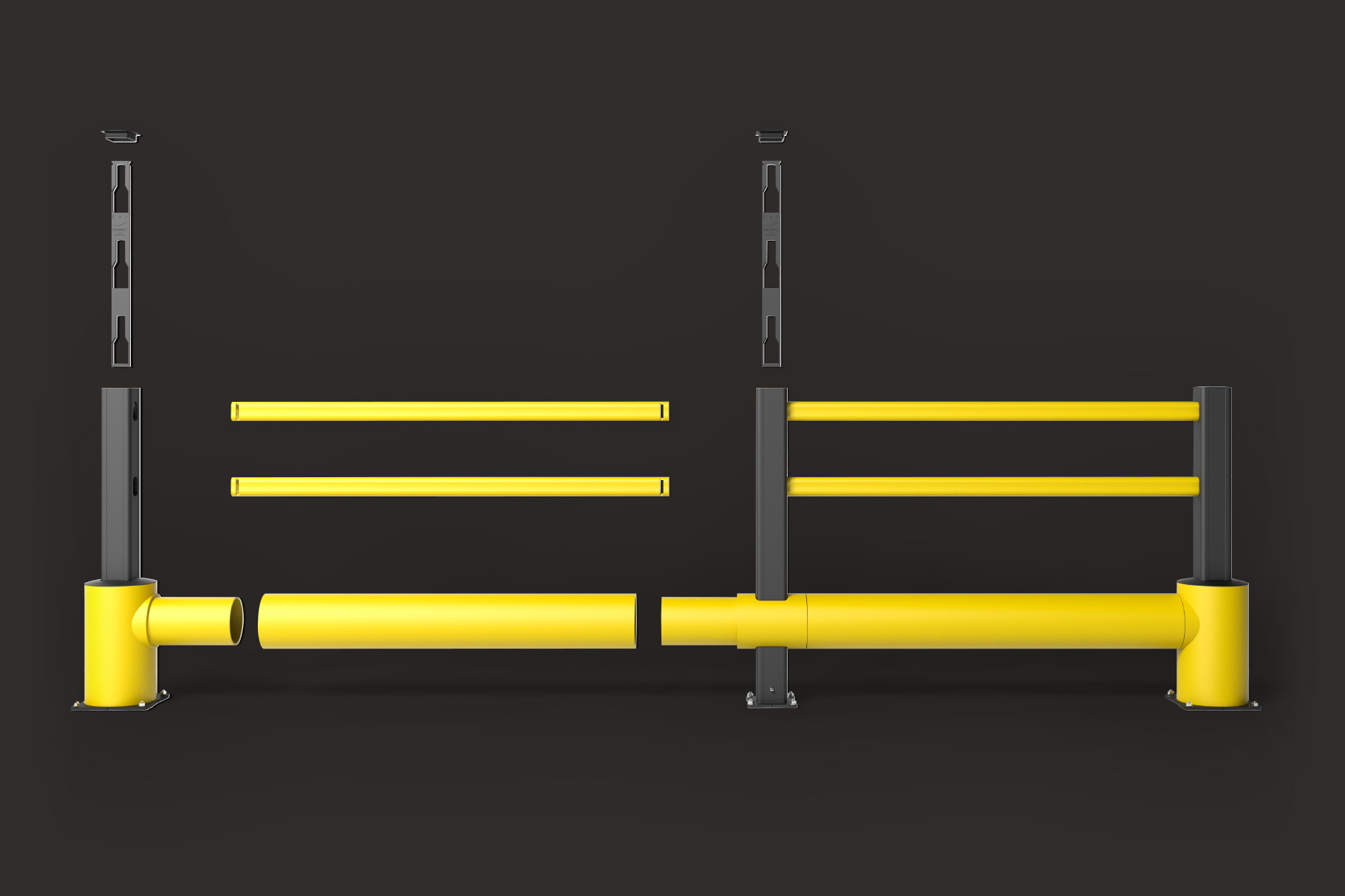

Modular design

Our polymer safety solutions are modular. No screws or bolts are required to interlock the parts, which allows some freedom of movement between the different elements. This 'loose' locking method reduces the risk of breakage on impact. Polymer is also easy to customize. A good example of this is the KP UNIVERSAL column protector. Because of its design, it can be made to fit any size column. This can be done by sawing the arms of the construction until it fits perfectly on the column. Working with steel in this way is a completely different matter.

Colorfast and highly visible

Unlike steel, polymer safety equipment is not painted. It is made entirely of colored material. A damaged steel construction will lose its color, which is not possible with a polymer construction. Yellow is the best color for polymer safety equipment, but other colors are possible. In addition, it can easily be fitted with luminescent or reflective strips.

Environmentally friendly

At a time when sustainability and environmental awareness are becoming increasingly important, polymer safety barriers offer an environmentally friendly alternative. Our polymer is fully recyclable and the manufacturing process has a lower environmental impact compared to traditional steel solutions.

Durability and longevity

Corrosion resistant

One of the biggest disadvantages of steel barriers is their susceptibility to corrosion. Especially in wet and chemically aggressive environments. Polymer barriers, on the other hand, are completely immune to corrosion. This ensures a longer lifespan and lower maintenance costs in the long run.

Weatherproof and resistant to toxic substances

Another weakness of steel is the potential for rust due to weather conditions. Paint can slow down this process, but corrosion will eventually occur. Polymers are not subject to oxidation at all. Environments where chemical products are processed or used are also no problem for polymer safety barriers.

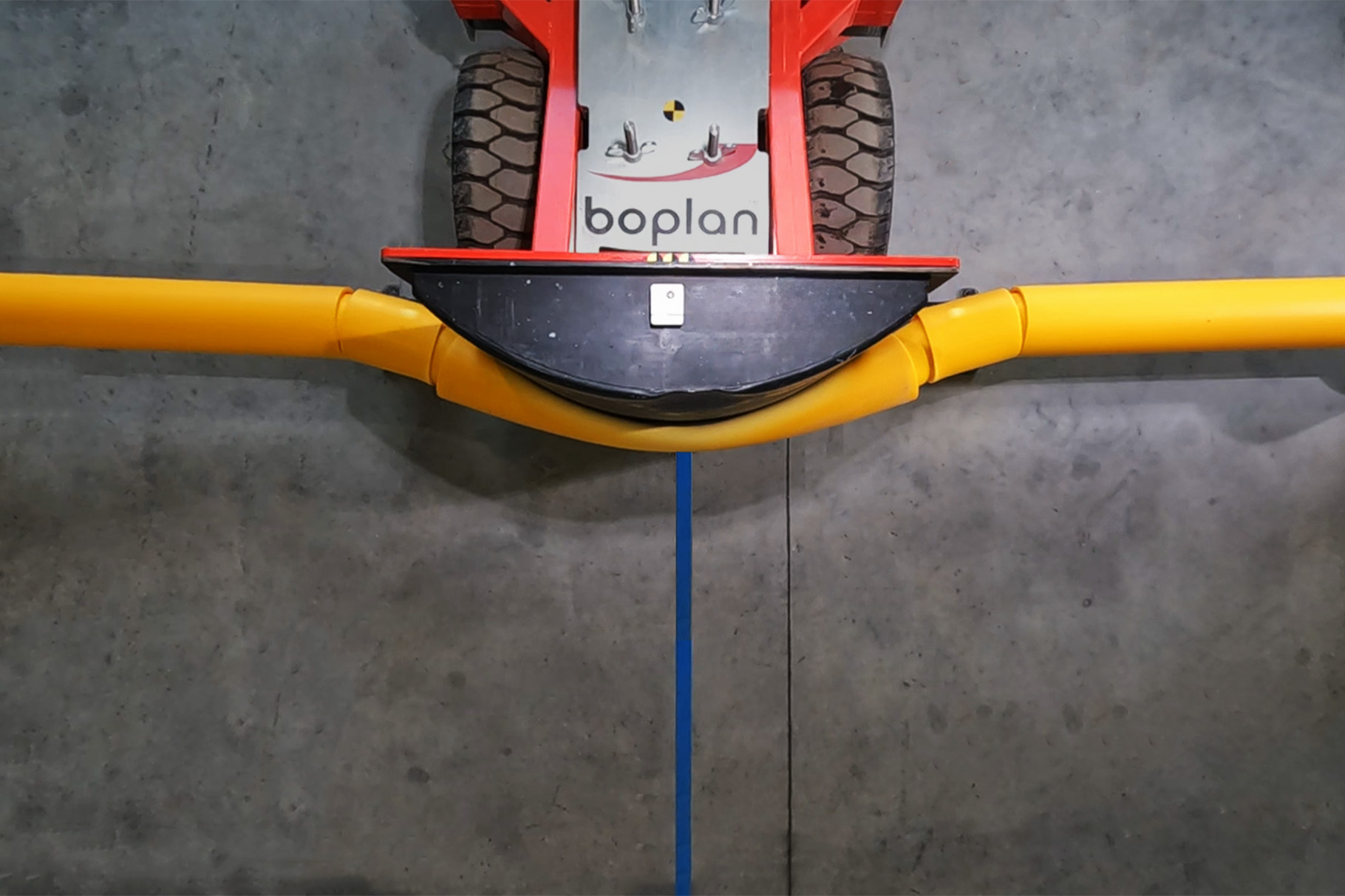

No floor damage

When a forklift truck hits a steel bollard, there is a chance that the bollard will be pushed out of the floor. The consequence: damage to both the forklift and the floor - a double repair cost. A polymer protective fence or bollard leaves the floor intact because it absorbs the force of the impact and distributes it over the entire area of the safety equipment.

Conclusion

As you can see, polymer safety products offer significant advantages over steel solutions in industrial environments. Polymer is a forward-looking choice that enhances safety and also improves the operational efficiency and sustainability of your facility.