Safety solutions at new Fahrenheit Logistics Netherlands B.V. distribution center

Fahrenheit Logistics Netherlands B.V., a leading distribution company and part of the Famalco Group, needed robust, durable, and aesthetically-pleasing safety solutions in order to protect its employees and infrastructure from heavy forklift traffic at its new distribution center. Boplan delivered and installed various protection products, including bollards, safety barriers, and kick rails, helping to greatly increase the overall safety and efficiency of the work environment. Learn more about this project in the video.

THE Challenge

This prominent logistics service provider was looking for robust, durable, and aesthetically-pleasing safety solutions for its new distribution center in Breda. A solid approach was required for this facility in order to prevent safety incidents and protect infrastructure, gates, and columns from collision damage.

Because of its heavy forklift traffic and fragile infrastructure, Fahrenheit Logistics turned to Boplan’s expertise in order to make its workspace safe and secure with innovative and impact-resistant products. The high-quality products from Boplan's FLEX IMPACT® range, including safety barriers, column protectors, and bollards, proved to be the perfect solution. We also equipped their freezer rooms with products from our ICE FLEX® range. Our ICE FLEX® products are capable of withstanding extreme temperatures (-22°F).

Watch this video see the final result

Our safety solutions

After performing a thorough analysis of Fahrenheit Logistics’ needs, we installed a combination of products from our FLEX IMPACT® and ICE FLEX® ranges.

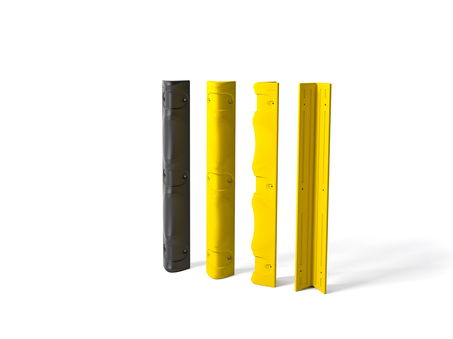

Bollards

Fahrenheit Logistics wanted safety products that would not need to be replaced after a collision. Since our safety solutions are extremely impact-resistant and flexible, they are able to absorb the force of a collision and return to their original position after the impact. This is a useful feature for safety bollards or barriers protecting gates, entrances, and openings. In the distribution center, we installed protection bollards from our FLEX IMPACT® range. Our bollards absorb the force of impact to prevent damage to infrastructure, vehicles, or the bollards themselves, which helps to reduce repair costs and downtime.

We also installed bollards from our ICE FLEX® range in their freezer rooms. Our ICE FLEX® safety solutions provide the same robust protection as our FLEX IMPACT® range, but with the added benefit that these products remain flexible even at temperatures well below freezing (-22°F). Boplan's safety barriers, bollards, and other products protect pedestrians and infrastructure from hazards, even in the coldest parts of your facility.

Kick rails

In addition to protecting gates and columns at the distribution center, we wanted to ensure that its walls remained protected from collisions with forklift forks and wheels. We therefore installed special kick rails along the walls and the lower sections of infrastructure at this facility. These kick rails create a strong barrier that prevents the wheels and forks of forklifts from hitting and damaging walls.

We chose Boplan because of their reputation as a leader in industrial safety. Boplan's solutions are not just effective and reliable, they are also durable and cost-effective. In addition, Boplan's customer-centric approach makes them a strong strategic partner for safety.