Polymer safety solutions protect pedestrians and infrastructure at AZA Logistics

AZA Logistics needed robust safety solutions to protect pedestrians and infrastructure from collisions with forklifts. It had numerous overlapping traffic routes, resulting in a high risk of accidents and collisions. To minimize accidents and avoid collision damage, AZA Logistics chose Boplan polymer safety solutions. We offered them the right solution for all of their safety issues, from safety barriers and handrails to rack protectors and bollards.

Challenge

Safely demarcating different traffic routes is not easy at busy logistics centers like AZA Logistics. Traffic must be able to circulate easily and efficiently, but this must never compromise safety. To keep pedestrians safe and protect its infrastructure, AZA Logistics needed well-designed, user-friendly, high-performance safety solutions. Boplan proposed a mix of safety solutions involving safety barriers, rack protectors, bollards, and impact protection.

OUR SAFETY SOLUTIONS

RACK PROTECTORS PREVENT DAMAGE TO RACKS AT AZA LOGISTICS

We installed our RE RACK END to protect the vulnerable ends of their stacking racks. This solution prevents forklifts from hitting rack corners and causing a domino effect when they drive into a warehouse aisle. This is essential in a busy distribution center such as AZA Logistics.

Safety barriers with handrails

Considering the predicted type of impact, we proposed two types of impact protection:

We used the TB 260 PLUS in pedestrian environments because its integrated handrails clearly separate pedestrian pathways from material stacking areas. This system provides good visibility, guidance, and impact protection up to 46.5 kJ.

We used the TB 400 PLUS in areas where forklifts maneuver that require less impact resistance. The TB 400 PLUS provides impact protection up to 21.1 kJ.

WE CHOSE BOPLAN AS OUR SAFETY EXPERT BECAUSE IT OFFERS THE BEST VALUE FOR OUR MONEY. BOPLAN'S PRODUCTS ARE BOTH IMPACT-RESISTANT AND LOW-MAINTENANCE. THIS WILL SAVE US A LOT OF MONEY IN THE LONG RUN, BECAUSE WE DON'T HAVE TO REPLACE OUR PROTECTION SYSTEM AFTER AN IMPACT. WE COULDN'T BE MORE SATISFIED AS A CUSTOMER.

Bollards FOR PROTECTION AT CRITICAL POINTS

We installed BO IMPACT bollards at the most critical points in the production center. These bollards were specially designed for areas that are at risk of frequent impacts, for example, near large doors, entrances, and machines.

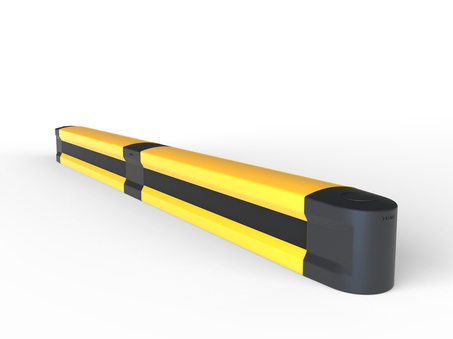

FLIP 180M KICK RAILS PROTECT VULNERABLE INFRASTRUCTURE

Kick rails protect infrastructure like columns from damage. The FLIP 180M prevents forklifts from hitting columns or other pieces of infrastructure with their forks. These kick rails can also be used as wheel guides.

About AZA Logistics

AZA Logistics is a logistics company based in Valencia. It asked Boplan to provide various safety solutions for its 742,709 sq ft (69,000 m²) site. We used safety barriers, bollards, and rack protection to take this site's safety to the next level.

Do you want to take your company's safety to the next level?