Loading dock optimization: safe and efficient loading dock operations

The loading dock is the beating heart of any logistics operation. A well-equipped loading dock combines a carefully designed layout, efficient loading facilities and great attention to safety. This blog post describes what to consider when designing a loading dock and which safety solutions are indispensable. That way you won’t just optimize your logistics flow, you can also ensure maximum protection for workers and equipment.

What is a loading dock and why is it important?

A loading dock is an essential element of any warehouse, distribution center or industrial facility where goods get loaded or unloaded. A well-designed loading dock increases the efficiency, safety and throughput of goods flows.

A poorly equipped loading dock can cause delays, damaged goods and vehicles, and even accidents. That’s why it’s crucial to pick the right features and layout to fit your business’s specific needs.

Key elements of an efficient loading dock

Dock levelers

Dock levelers bridge the height gap between the truck and loading dock, ensuring smooth loading operations. They are available in different versions, including hydraulic, mechanical and pneumatic systems.

Dock shelters & dock seals

Dock shelters and seals protect against the elements, reduce energy waste and ensure a safe, comfortable work environment.

Safety features

A safe loading dock prevents damage to vehicles, infrastructure or employees. Important safety features:

- Safety barriers: prevent collisions with your building.

- Wheel stops and dock locks: keep trucks from moving.

- Signaling systems: improve communication between drivers and staff.

Automatic loading dock systems

Automated systems such as sensor-controlled dock levelers and vehicle detection can also help further optimize operations.

Prevent accidents and damage

Loading dock safety

A loading dock that isn’t safe can lead to serious accidents. Important areas of attention:

- Use clear lines and markings.

- Ensure non-slip surfaces.

- Provide sufficient space for trucks to maneuver.

- Perform regular inspections and maintenance.

- Train workers to work safely around loading docks.

In addition, companies need to comply with regulations and safety standards to minimize the likelihood of incidents. For example, ANSI MH30.1 and OSHA 1910.26 set out specific requirements for dock levelers to ensure a safe transition between the warehouse and the vehicle.

Learn more on how to avoid workplace accidents on a loading dock.

Loading dock protection from Boplan

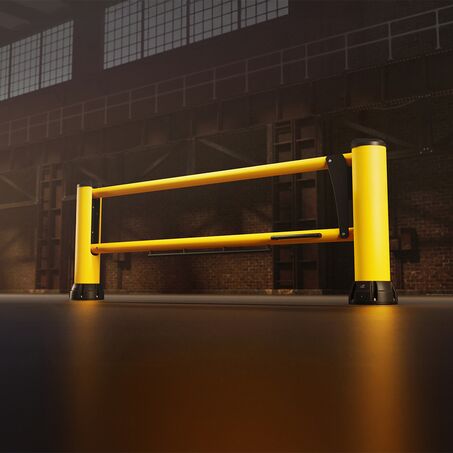

To maximize loading dock safety, Boplan offers advanced solutions such as Dock Gates and Dock Bumpers:

- A dock gate is a safety gate to prevent workers from accidentally falling off a loading dock. It provides additional protection in case of an open loading dock.

- Robust, wear-resistant Dock Bumpers are attached to the edges of the loading dock to help absorb the impact from reversing trailers.

Implementing such systems significantly increases safety on and around loading docks.

Learn more on how to avoid workplace accidents on a loading dock.

Choosing a loading dock: what to look out for

When choosing a loading dock, consider the following:

- Types of freight traffic: which vehicles will use the loading dock?

- Available space: is there sufficient space for trucks to maneuver?

- Sector-specific requirements: do you need additional protection against temperature fluctuations or moisture?

- Cost-benefit: an efficient loading dock creates long-term savings.

Conclusion: a cleverly designed loading dock increases safety and productivity

A safe, well-designed loading dock supports smoother logistics processes. By investing in the right equipment, automation and safety measures, you can optimize the flow of goods and minimize your risks.

Would you like advice on the best loading dock solutions for your business? Get in touch and find out how to maximize your loading dock’s safety and efficiency!