Loading dock optimisation: efficient and safe loading and unloading

The loading dock is the beating heart of any logistics operation. A well-equipped loading dock combines a well thought-out layout, efficient loading facilities and a strong focus on safety. In this blog, you will discover what to look out for when designing a loading dock and what safety solutions are indispensable. This will allow you both to optimise your logistics flow and ensure maximum protection for your employees and equipment.

What is a loading dock and why is it important?

A loading dock is an essential part of any warehouse, distribution centre or industrial facility where goods are loaded and unloaded. A well-designed loading dock increases the efficiency, safety and throughput of goods flows.

A poorly equipped loading dock leads to delays, damage to goods and vehicles, and even accidents. That’s why it’s crucial to choose the right amenities and layout that is tailored to the specific needs of your business.

Key components of an efficient loading dock

Dock levellers

Dock levellers bridge the height difference between the truck and the loading dock to ensure loading and unloading runs smoothly. They come in different versions, such as hydraulic, mechanical or air-powered systems.

Dock shelters & dock seals

Dock shelters and dock seals protect loading dock areas against the elements, reduce energy loss and ensure a safe and comfortable working environment.

Safety solutions

A safe loading dock prevents damage to vehicles, infrastructure and employees. Some important safety features:

Safety barrier: prevents collisions with the building.

Wheel stops and dock locks: keep trucks in place.

Signallingsystems: improve communication between drivers and staff.

Automated loading dock systems

Automated systems such as sensor-controlled dock levellers and vehicle detection devices are also available to further optimise processes.

Prevent accidents and damage

Loading dock safety

An unsafe loading dock leads to serious accidents. This is why it is important to:

Use clear lines and markings.

Install non-slip surfaces.

Allow sufficient manoeuvring space for trucks.

Perform regular inspections and maintenance.

Train employees in safe working practices around loading docks.

Companies also have to meet regulations and safety standards to minimise the likelihood of incidents. EN 1398, for instance, sets specific requirements for dock levellers to ensure a safe transition between the vehicle and warehouse.

Read more about how you can avoid loading dock bay accidents in the workplace.

Boplan loading dock protection

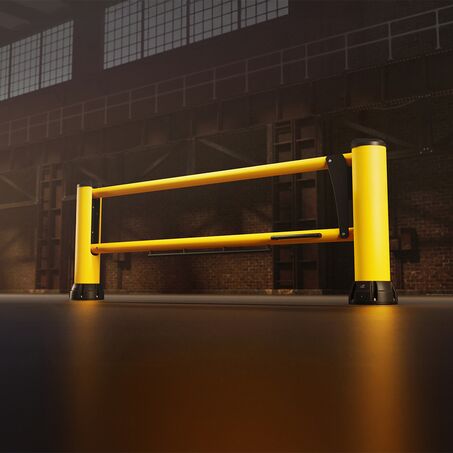

To maximise loading dock safety, Boplan offers advanced solutions such as dock gates and dock bumpers:

A dock gate is a safety gate that prevents employees from accidentally falling off the loading dock. They provide extra protection when the loading docks are open.

The robust, wear-resistant dock bumpers are attached to the loading dock's exterior to absorb the shock of reversing trailers.

Implementing these systems significantly increases safety on and around the loading dock.

Read more about how you can avoid loading bay accidents in the workplace.

What to look out for when choosing a loading dock

When choosing a loading dock, you need to consider:

Type of freighttraffic: what vehicles will be using the loading dock?

Available space: is there sufficient manoeuvring space for trucks?

Sector-specific requirements: do you need extra protection against temperature fluctuations or humidity?

Cost versus return: an efficient loading dock leads to long-term savings.

Conclusion: a cleverly designed loading dock increases safety and productivity

A well-designed and safe loading dock contributes to a smooth logistics process. By investing in the right facilities, automation and safety measures, you optimise the flow of goods and you minimise the risks.

For advice on the best loading dock solutions for your business, get in touch and find out how you can maximise the efficiency and safety of your loading dock!