Top-quality safety solutions for chocolate producer Belcolade

At Belcolade, everything revolves around quality. From growing the cocoa bean to the final product loved worldwide. Every step of their production process is carried out with the utmost care. This commitment to quality extends beyond taste—it also shapes their safety policy. For years, Belcolade has relied on Boplan’s expertise and safety solutions to provide the best possible protection for employees and infrastructure.

Curious to know how we make it work? Read on to discover our long-standing collaboration.

Separating walkways from forklift traffic

The challenge

Protecting pedestrians and infrastructure from collisions

Our safety solutions at Belcolade

A safe workplace starts with insight. That’s why Boplan and Belcolade began with a thorough analysis of the site’s risk zones and workflows. Where do pedestrians cross paths with forklift traffic? Which passages are critical, and where is the risk of damage highest?

The result was a well-considered mix of impact-resistant solutions from the FLEX IMPACT® range. Each with a specific role in the manufacturing environment.

Height restrictors with Touch Barriers

We installed Goal Posts at gates, passageways and forklift lifts. These robust height restrictors protect at height against forklift collisions. Their striking yellow colour heightens forklift drivers’ awareness in critical locations. Touch Barriers are mounted on the Goal Posts. An over-height load or forklift first makes contact with this beam. The gentle contact serves as an immediate warning to the driver. Preventing damage to gates, lifts or other infrastructure before it occurs.

Safety bollards were strategically positioned where structural protection matters most: at gates, columns, line guards and at pedestrian–forklift crossings. These durable posts absorb heavy impacts and then return to their original shape, without causing damage to the floor or the vehicle. In addition, these safety bollards also serve a clear guiding function. They guide internal traffic safely and improve the flow on the shop floor.

The TB 400 PLUS safety barrier protects pedestrians

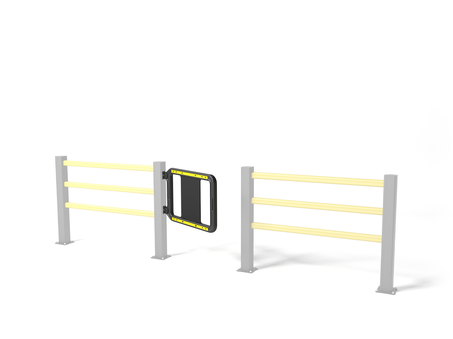

Safe walkways with flexible safety barriers and safety gates

To prevent pedestrians from entering forklift zones and being directly exposed to traffic, Boplan installed more than 110 metres of TB 400 PLUS safety barriers. This FLEX IMPACT® safety barrier combines our single-tube TB 400 safety rail with the HP PLUS handrail.

This installation is mounted on removable base plates. This type of mounting allows barriers, gates or handrails to be easily removed and reinstalled. This flexibility is useful during maintenance or to provide temporary access for forklifts.

Safety gates for controlled access

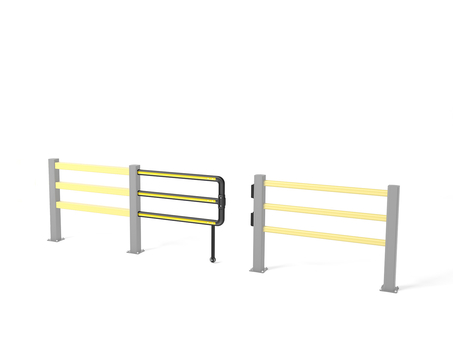

At Belcolade, we integrated several safety gates into the safety barrier system. Both the SWING GATES and SLIDING GATES are mounted on the robust TB 400 PLUS barriers.

The FLEX IMPACT® SWING GATE is a bi-directional safety gate that closes automatically. In environments where corridors or technical rooms are often left open by mistake, this gate provides an effective solution. The automatic closing function ensures the passage is always secured. This prevents pedestrians from inadvertently entering hazardous zones.

The SLIDING GATE is a sliding gate that opens and closes smoothly on a robust floor-mounted wheel. When opened, the rails slide neatly into the profiles of the adjacent handrail. This keeps the impact on available space to a minimum.

This SLIDING GATE also connects to a support on a removable base plate. The support can be removed to temporarily create a wider passage. A unique application in this project, fully tailored to the needs of a modern manufacturing environment.

Fall protection

Falls from height are among the most serious workplace accidents in industrial environments. Belcolade therefore opted for structural fall protection on elevated platforms and mezzanines. Boplan installed the DOUBLE AXES GATE at cage ladders and stair openings.

This TÜV NORD-certified solution is ideal for working at height. For example, elevated work platforms, mezzanines or technical zones at height. The DOUBLE AXES GATE closes automatically. Both when ascending and descending the ladder or stairs. This ensures the opening is never left unprotected.

Did you know this gate is already in its third generation? The latest version is made entirely of HI-TEP – an exceptionally strong and durable polymer, developed exclusively by Boplan®. This 100% recyclable material makes it the most sustainable safety gate in the world.

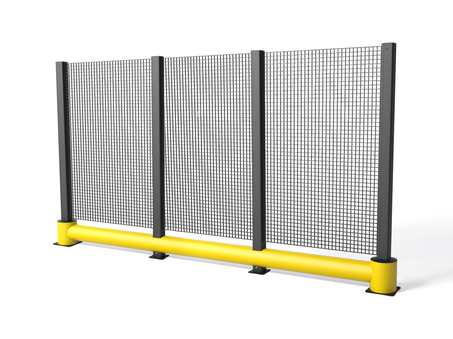

The TB 260 FENCE protects conveyors

Automated conveyor systems are a vulnerable part of a manufacturing environment. : At Belcolade, additional protection was needed for an automatic conveyor belt.

To protect this system from impact and damage, Boplan installed the TB 260 FENCE. This robust solution combines a low safety barrier with an integrated guard wall.

Protection of fire safety equipment

At Belcolade, Boplan installed red safety solutions around fire safety equipment such as sprinklers, fire hoses and emergency control systems. The colour enhances visibility in an emergency and fits seamlessly into Belcolade’s prevention policy.

Want to know more? Read our blog on collective protective measures for fire safety.

TB MINI: effective floor-level safety barrier

In areas where light rolling equipment such as pallet trucks, carts or smaller transport vehicles is used, low-level safety barriers are also essential. At Belcolade, the TB MINI fulfils this role. With an impact resistance of 5 kJ, this compact barrier consists of a single tube strategically positioned just above floor level. It provides clear guidance and serves as an effective buffer against low-height collisions.

Wall protection at floor level

Rolling equipment and forklift forks can quickly cause damage to walls, panels or machinery during manoeuvres. To prevent this, Belcolade installed the FLIP kick rail. This low yet highly robust protection solution is specifically designed for floor-level applications. Thanks to its modular design, the kick rail is easy to adapt to the shape of the wall.

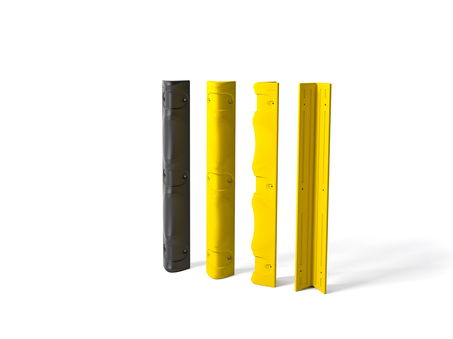

Targeted protection with corner protections and column protection

Belcolade’s manufacturing environment contains several structural elements such as columns and pillars that are vulnerable to collisions. To prevent damage to both infrastructure and vehicles, Boplan installed corner protections and column protection.

Touch Barriers

Smart height restriction with signal function

Did you know that you can use Touch Barriers not only as signalling at gates, but also as a smart solution in stacking zones?

At Belcolade, these polymer tube profiles are mounted above pallet stacking areas. They set the maximum stacking height in a simple yet effective way. An over-height pallet or load strikes the Touch Barrier, alerting the forklift driver.

DOCK GATE

A safety gate with an impact-resistant barrier arm

DOCK GATE restricts access to specific areas while increasing employee awareness. The physical presence of the gate creates a clear boundary between safe and high-risk zones. This strengthens safety awareness and prevents unauthorised access.

This solution combines three key functions: protection, visual demarcation, and controlled access. Ideal for locations where extra vigilance is required.

TB 260

Reliable protection for industrial boilers

The TB 260 protects the large industrial boilers at Belcolade from collisions. This robust safety barrier from the FLEX IMPACT® range forms a strong buffer between traffic routes and vulnerable installations. Exactly where the risk of impact is highest.

With its high impact resistance, the TB 260 absorbs collisions, preventing damage to the floor, the vehicle, or the installation. After a collision, the barrier springs back to its original shape. This avoids costly repairs or replacements.

The striking yellow colour increases visibility in busy areas, while the modular design allows the protection to be tailored precisely to the available space.

Result

Thanks to its partnership with Boplan, Belcolade is assured of a safe, efficient working environment that perfectly matches its vision. Every zone on the site is carefully organised. Risk zones are clearly defined. Pedestrians and vehicles are safely separated, and critical installations remain permanently protected from impact. The flexibility of the safety solutions makes maintenance easier than ever.

Genuine quality goes beyond our chocolate. It’s also about protecting our people. Boplan helps us make this a reality. The solutions are easy to maintain, flexible, durable—and above all, reliable.

About Belcolade

Belcolade is the benchmark for top-quality Belgian chocolate. As part of the Puratos Group, the company supplies sustainable chocolate worldwide that meets the highest quality standards. They apply those same high standards to safety. This is why Belcolade has trusted Boplan’s expertise for years. We installed a wide range of safety solutions there, from safety barriers and bollards to height restrictors, kick rails and safety gates.

Curious how our safety solutions can make your manufacturing environment safer? Get in touch!