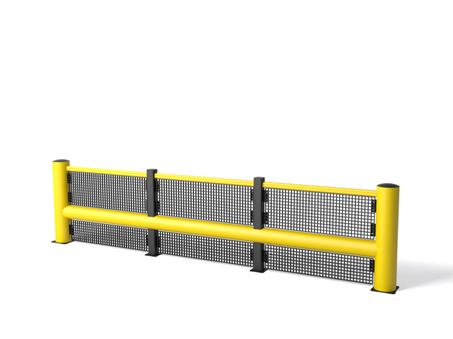

FLEX IMPACT® safety barriers are a form of impact protection specifically designed to protect machinery and buildings from collisions with forklifts or other heavy vehicles. These impact protection materials are designed for high-speed traffic environments or locations where heavy loads are moved or transported, such as warehouses, construction sites and airports.

What is unique about our safety barriers is that, even in the event of a collision, the anchor points are not torn out of the ground and the flexible elements retain their original shape after impact. The modular design of the safety barriers gives you the opportunity to complete your company's impact protection one zone at a time, or choose to expand at a later date.

Effective crash protection can prevent serious and even fatal accidents. It is therefore very important not to make a hasty decision, but to make a well-informed choice based on the right criteria.

Boplan offers a wide range of crash protection systems for light rolling material. These are ideal for areas with mixed pedestrian and forklift traffic where there is a significant risk of impact. They also provide protection low to the ground and protect pedestrians from poorly stacked or falling products. In addition to the safety barrier range, Boplan also offers protective posts and safety gates, column and corner protection, pallet rack protection, edge protection and wheel stops, loading dock protection and protective bumpers.

Safety barriers are a safety solution whose primary function is to protect infrastructure, buildings and pedestrians from damage and collision by vehicles in the workplace. It is also used to keep designated routes clear by effectively separating traffic. Boplan offers different types of safety barriers that can be combined with other types of safety products. Consider, for example, a combination with a handrail system.

Boplan safety barriers have the following advantages:

Plastic safety barriers cost more to purchase than steel crash barriers. This is because the manufacturing and material costs of plastic are higher than those of steel. However, due to its durability, long life and low maintenance costs, the Total Cost of Ownership (TCO) of plastic safety barriers is much lower than that of steel.