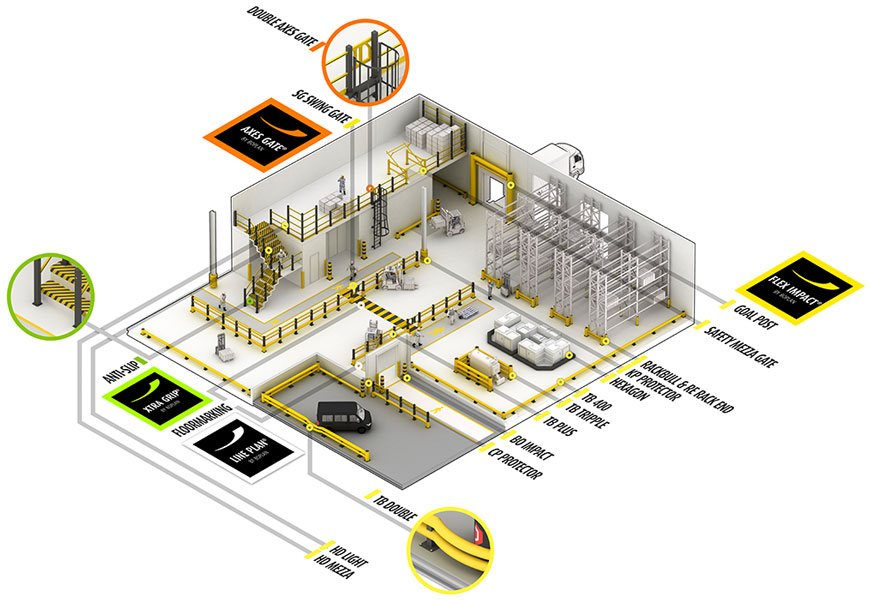

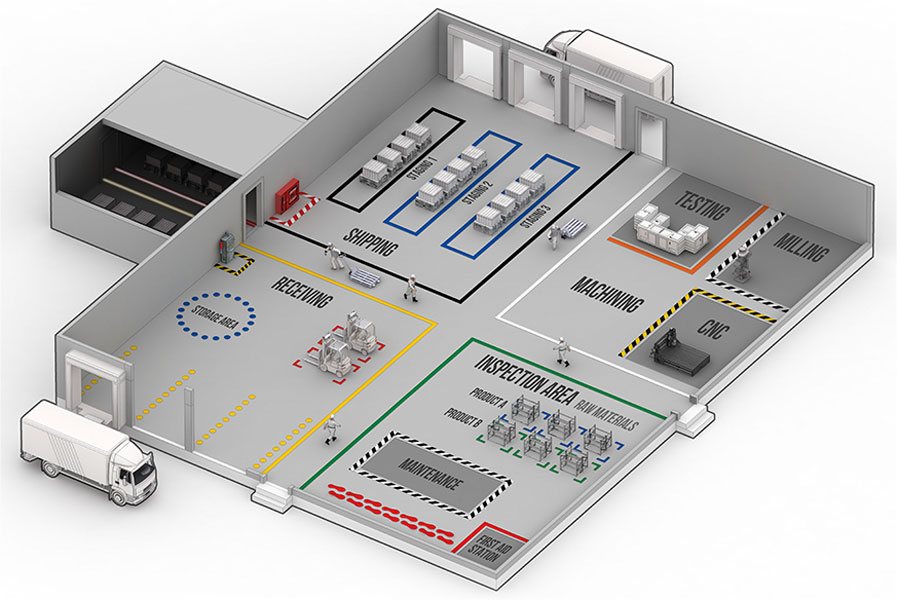

Rack protection for stackable racks, impact protection for loading bays, and protection for pedestrians and vehicles in the workplace are just a few examples of where our safety equipment is used most frequently to create a safe working environment.

Rack protection for stackable racks and impact protection for loading bays

Protection of packaging machines, pillars or columns

Protection for packaging machines, pillars or columns: physical barriers for workplace zones

Protection of large machines and conveyor belts

Safety measures for large machines and conveyor belts and physical barriers around high-risk danger zones in the workplace are just a few examples of where our polymer FlexImpact impact protection can be found.

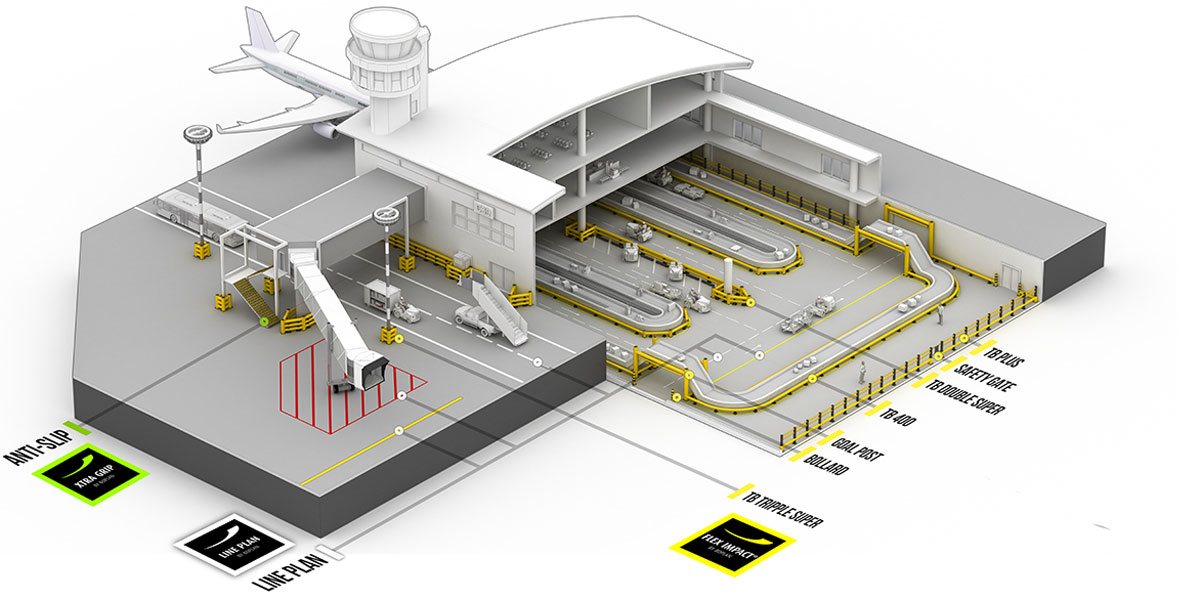

Protection against baggage handling carts, shuttle or golf carts

Boplan’s polymer FlexImpact impact protection systems are ideal for any airport area where baggage carts, shuttle carts or golf carts need to drive. Protection for baggage handling and conveyor belts is in high demand in the airport industry.

Impact protection in toxic, high-saline & corrosive environments

Fall and impact protection has to be chemical-resistant in these extremely demanding environments, where toxic substances are frequently used. Offshore drilling platforms, for example, benefit from our extremely weather-resistant safety products, made from polymers that can handle high-saline & corrosive environments.

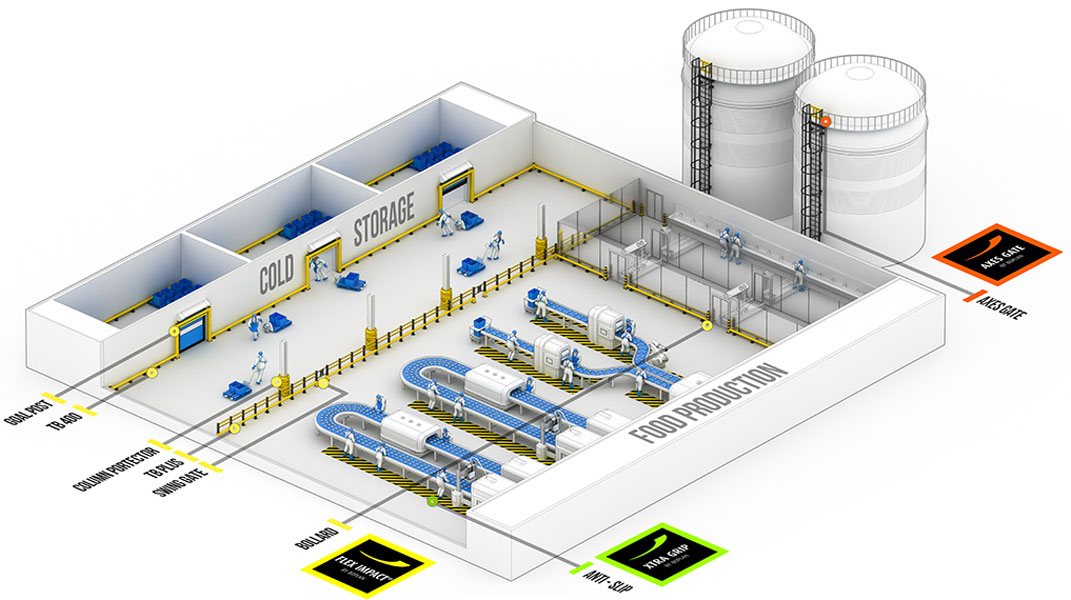

Impact protection in food industry

Hygiene is vital in the food industry. Our FlexImpact impact protection systems is completely resistant to rust & corrosion. Boplan safety equipment made from synthetic polymers is perfect for extremely demanding environments in the food industry. The ICE FLEX® range of safety products was specifically developed for use in sub-zero temperature environments of up to -30°C or -22°F.

Collision protection for industrial cold storage

With the ICE FLEX® range, BOPLAN® offers numerous safety solutions that have been specifically designed and tested for use in freezing temperatures down to -30°C or -22°F. The standard BOPLAN® polyolefin has been adjusted so that the ICE FLEX® products offer optimum impact protection and maximum safety even in freezing conditions.

Processing and storing cooled and deep-frozen products often involve different work flows. For example, employees are only allowed to work in cold stores for short periods and must therefore work faster to complete their duties. In addition, heavy protective clothing limits their freedom of movement, glasses can fog-up, etc. These specific circumstances can create additional safety risks and require adapted solutions.